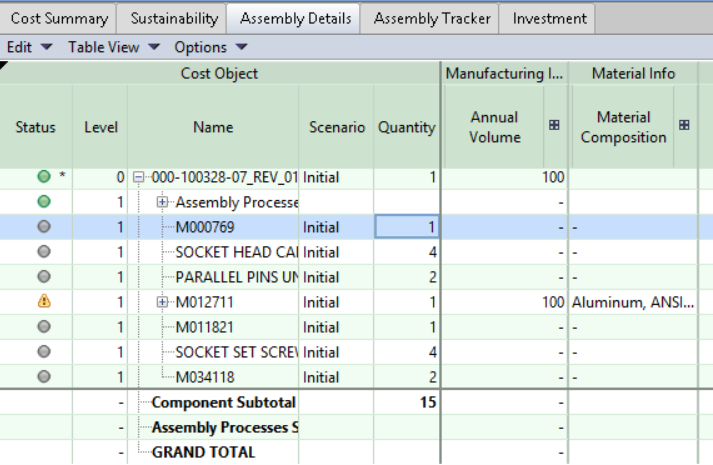

The Part Details and Assembly Details tabs display similar information about an analyzed part or assembly, and its cost for a given Digital Factory and process routing. For example:

Tip: See View Assembly Details for more details of assembly-specific information.

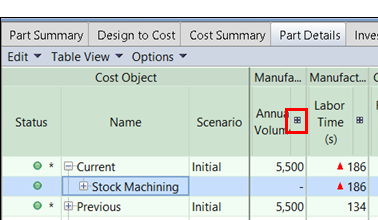

Click the (+) icon in any column header to expand this column:

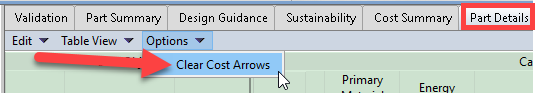

To hide the arrows showing recent value changes in cells (example:  ), select Options > Clear Cost Arrows.

), select Options > Clear Cost Arrows.

Fields Displayed

The Part Details and Assembly Details tables include the following fields.

|

Field |

Description |

|

|---|---|---|

|

Process |

Process |

The cost associated with a particular type of manufacturing process that a machine performs. |

|

|

Machine Name |

The machine used by the cost engine to compute costs for the given process. |

|

Manufacturing Times |

Labor Time (s) |

The time that someone is paid to perform an operation/process on one part/assembly. |

|

|

Cycle Time (s) |

The time that a machine/process is operating on a given part/assembly. |

|

|

Parts Per Hour |

Computed as 3600 seconds per hour divided by Cycle Time. |

|

Variable Costs |

Material Cost |

Cost of the physical material used in the manufacture of the part. Material Cost includes both the material in the physical part and an allocation of scrap material that is wasted during the manufacturing process. Material cost does not include consumable material for example, weld wire, adhesives, only primary material. |

|

|

Labor |

The amount that labor is paid to manufacture the part or assembly. The customer determines which components of labor compensation are included in the labor rate that is used to calculate labor cost. However, labor cost usually includes hourly wages and benefits. |

|

|

Direct Overhead |

Direct Overhead costs are costs that can be specifically associated with the manufacture of specific part through a machine. For example, most machines have a machine or direct overhead rate that allocates the machine's power costs, depreciation, maintenance to parts that run on the machine based on time. |

|

|

Batch Setup (amortized) |

The cost in machine downtime and labor incurred when a machine is configured to run a batch of a given design. This cost is amortized to individual parts or assemblies by the number of parts in a batch. |

|

|

Logistics |

The cost of transportation between supply chain facilities. |

|

|

Expendable Tooling |

Tooling that is consumed during manufacturing, but not tied to a specific part. For example, a drill bit, turret press punch, etc. are used in the manufacture on many different part designs. |

|

|

Additional Direct Costs |

Other miscellaneous costs not accounted for in the above categories. |

|

|

Extra Costs |

A placeholder line item to be used for miscellaneous costs. The default value is zero but your Digital Factory may be customized to use this field to capture specific types of costs and relabeled as needed, see the aPriori Administration Guide Managing Cost Taxonomy Display Labels. |

|

|

Other Direct Costs |

The subtotal of Expendable Tooling, Additional Direct Costs, and Extra Costs |

|

|

Total Variable Costs |

The sum of all cost items above, Total Variable Costs is the marginal cost associated with making “one more” part a give design. This includes all Variable Costs associated with the creation of a part but does not include depreciation of capital tooling. |

|

Period Costs |

Period Overhead Allocations |

Period or indirect overheads are expenses that are expensed each financial period (factory depreciation, light bills, SG&A) that cannot be associated or amortized to a specific design. |

|

Margin |

Margin |

The profit margin charged on each part/assembly. Calculated by multiplying a margin percentage value by the sum of the costs. The margin percentage defaults to 0 in the regional data libraries but can be configured by customers. |

|

Piece Part Cost |

Piece Part Cost |

The sum of all cost items above, Piece Part Cost is cost of making a part, including margin if applied but excluding fixed (tooling-related) costs. |

|

Fixed Costs |

Hard Tooling (amortized) |

Capital or hard tools are purchased for creating one specific design and cannot be used to create others. |

|

|

Fixture Cost (amortized) |

Devices used to hold a specific part or assembly in the correct orientation on a machine during manufacture or assembly. Fixtures and jigs under the Fixed Cost category are created for a specific design. It is assumed that these fixtures will not be re-used on a different design in the future. |

|

|

Programming Cost (amortized) |

The cost of creating a computer program that Computer Numerical Control (CNC) machines will follow to make or assemble parts of a specific design. |

|

|

Additional Amortized Investments |

Other miscellaneous costs not accounted for in the above categories. |

|

|

Total Amortized Investments |

The sum of all fixed costs. Fixed costs must be incurred before the first part or assembly of a given assembly made. In aPriori, all fixed costs are amortized to the individual part or assembly by dividing the total, up-front cost for the fixed cost (the capital cost) by the otal roduct olume. |

|

Fully Burdened Cost |

Fully Burdened Cost |

For parts, the sum of Piece Part Cost and Fixed Costs. |

|

Unit Cost |

Unit Cost |

For assemblies, the unit cost is the cost of one part, regardless of the quantity of parts in the assembly. |

|

Capital |

Hard Tooling |

Capital or hard tools are purchased for creating one specific design and cannot be used to create others. The Capital Cost is the price to buy one set of the tooling. |

|

|

Fixture Cost

|

Devices used to hold a specific part or assembly in the correct orientation on a machine during manufacture or assembly. Fixtures and jigs under the Fixed Cost category are created for a specific design. It is assumed that these fixtures will not be re-used on a different design in the future. The capital cost is the price to buy one set of the tooling. |

|

|

Programming Cost |

The cost of creating a computer program that Computer Numerical Control (CNC) machines will follow to make or assemble parts of a specific design. |

|

|

Total Capital Investment |

Capital investment is the total amount a company must invest in fixed costs before the first part or assembly can be made. This cost is fixed because the company incurs the cost whether it makes one part or the total number of parts allowable before tooling must be refurbished or replaced. |

|

Design Guidance |

Max Severity |

Severity level of the most severe design guidance issue(s) |

|

|

Critical Issues |

Number of design guidance issues that make the part unlikely to be manufacturable |

|

|

Major Issues |

Number of design guidance issues that pose a high risk of quality defects |

|

|

Minor Issues |

Number of design guidance issues that pose some risk of quality defects |

|

|

Cost Driving Issues |

Number of design guidance that affect cost, as when for example, a user-specified tolerance is not achievable by a primary process alone and so requires extra machining, driving additional costs |

|

|

Unclassified Issues |

Number of design guidance issues whose severity is not classified. |

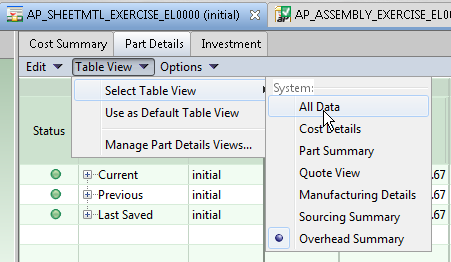

Select Table Views

Both the Part Details and Assembly Details tab provide pre-defined views that you can display to focus on specific area of interest.

Click Table View >Select Table View to choose a view:

Select the All Data view to show all data fields available for the part, grouped into categories.

Configure Views

You can configure information into different views, to show:

-

Current cost and quote data

-

Production information

-

Digital Factory, process, and machine information

-

Manufacturing times and costs, and input rates such as hourly labor and overhead rates and material unit costs that are used in the cost computations.

Note: Some of the fields presented in these views are editable. See Override Computed Values for more information.

To change the results viewed, create a new custom view. See Create a New View